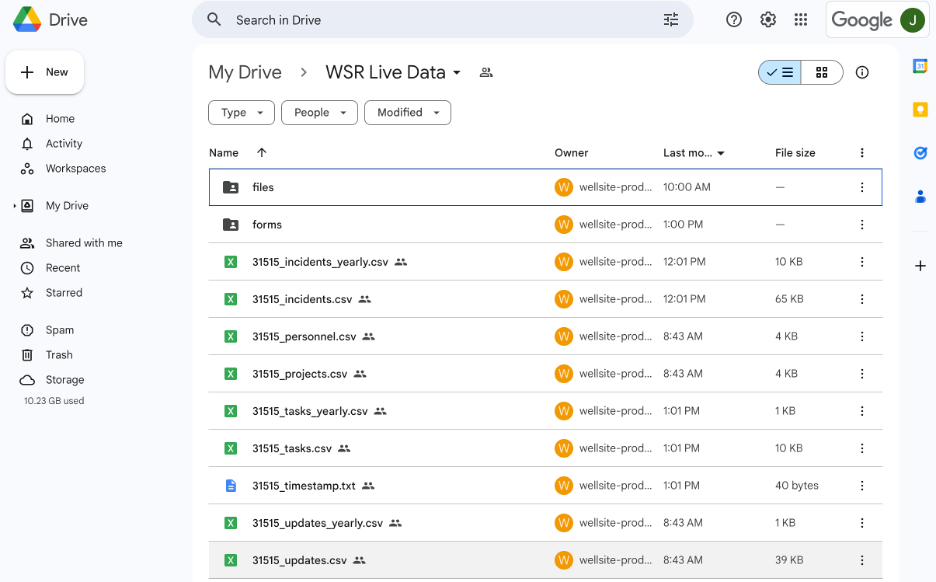

Access all your data effortlessly in a Google Drive folder of your preference, eliminating the need for manual exports. From core application data to forms and files, everything you need is readily available. Stay up-to-date with the latest insights and information, conveniently at your fingertips.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

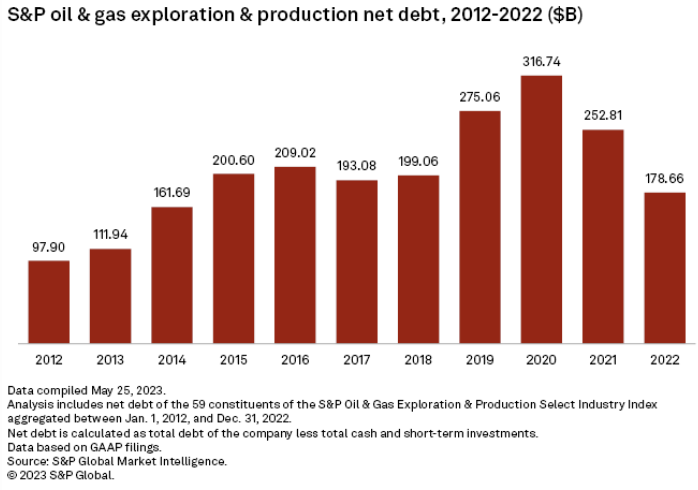

First, the good news. Since the height of the pandemic in 2020, exploration and production companies (E&Ps) have reduced their net debt from a high of $316.74 billion to $178.66 billion at the end of 2022. According to CreditSights senior analyst Charles Johnston, most independent E&Ps refinanced and now pay less than the double-digit interest rates of 2020. So, hat-tip for fiscal responsibility.

Now, the bad news. Interest rates are rising, which negatively impact E&Ps several ways. First, as borrowing costs increase, exploration activities slow down and reduce the overall growth potential of anticipated new production.

Second, higher interest rates negatively impact crude prices. For example, the New York Mercantile price of crude oil closed at $93.68 per barrel on September 27. Just a week later, as this blog was written, the price had gradually fallen approximately $10.00 at the close. Economists would point out that the price drop can be partly attributed to a prime interest rate of 8.50 percent. Typically, the prime rate is about three full percentage points higher than the effective federal funds rate (EFFR), which is the interest rate set for banks to lend to other banks. So what’s the big deal about the EFFR? In 2022, it was only 3.08 percent, which also means the lending rate to E&Ps was much lower than it is today.

Third, any E&P that refinanced to a better interest rate on an existing revolving line of credit in the last two years is about to see its debt payments recalculate to today’s significantly higher percentage rate. Gaurav Sharma, assistant director of strategy and research at Acuity Knowledge Partners, said that higher interest rates sustained over several quarters will negatively affect E&Ps’ future cash flows for capital expenditures as well as suppress demand for new oil and gas production.

The takeaway from this news about rising interest rates is that any company working in the oil and gas industry needs to better manage and maintain equipment to keep costs under control. That’s where Wellsite Report cloud-based software can make a difference to your bottom line.

Wellsite Report’s equipment module enables your company to better manage and maintain even the most unique items to make preventive maintenance routine and easy. Its custom associated fields allow for automatic updates of equipment information, and email triggers can be created based on a custom field association to keep everyone involved on the same page.

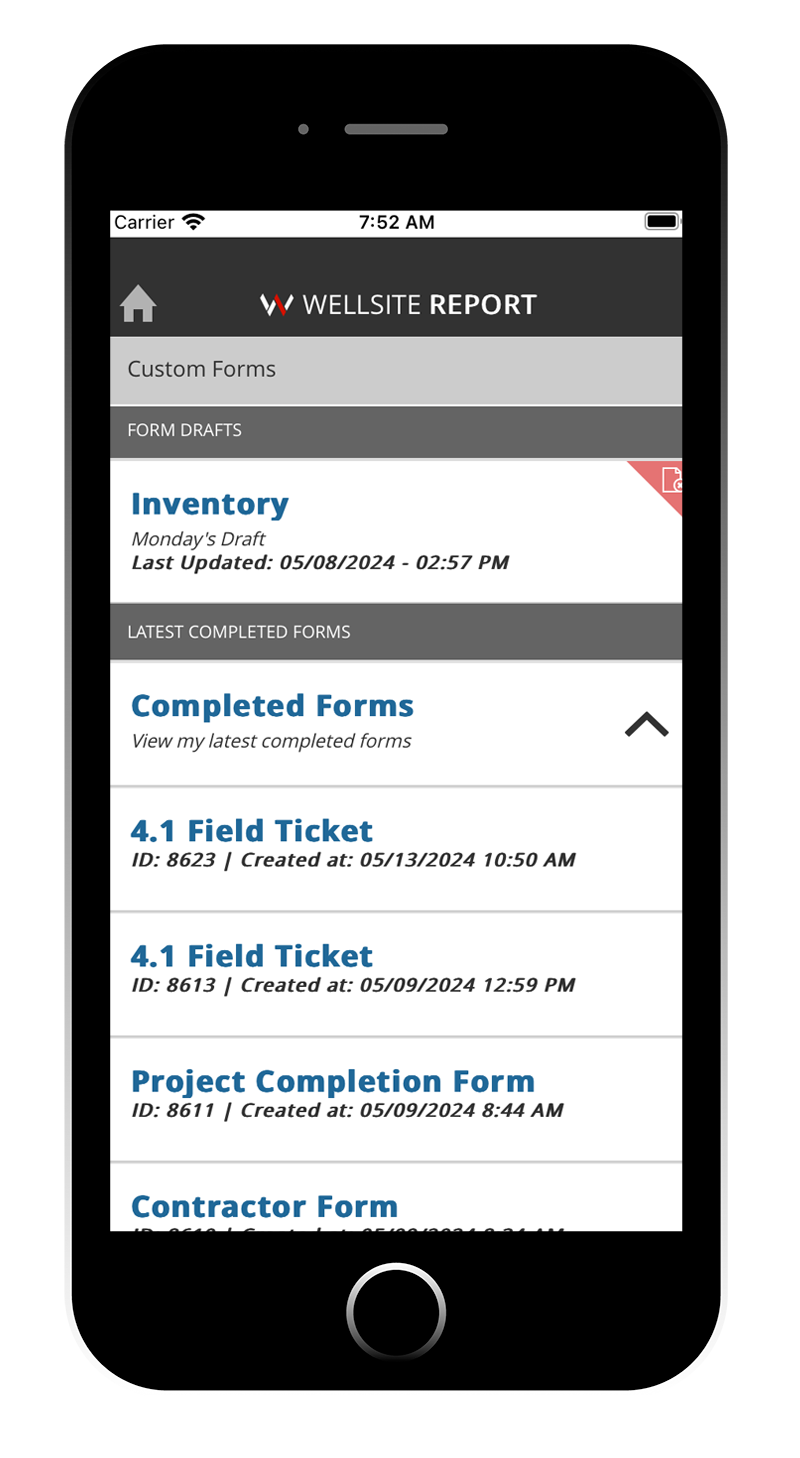

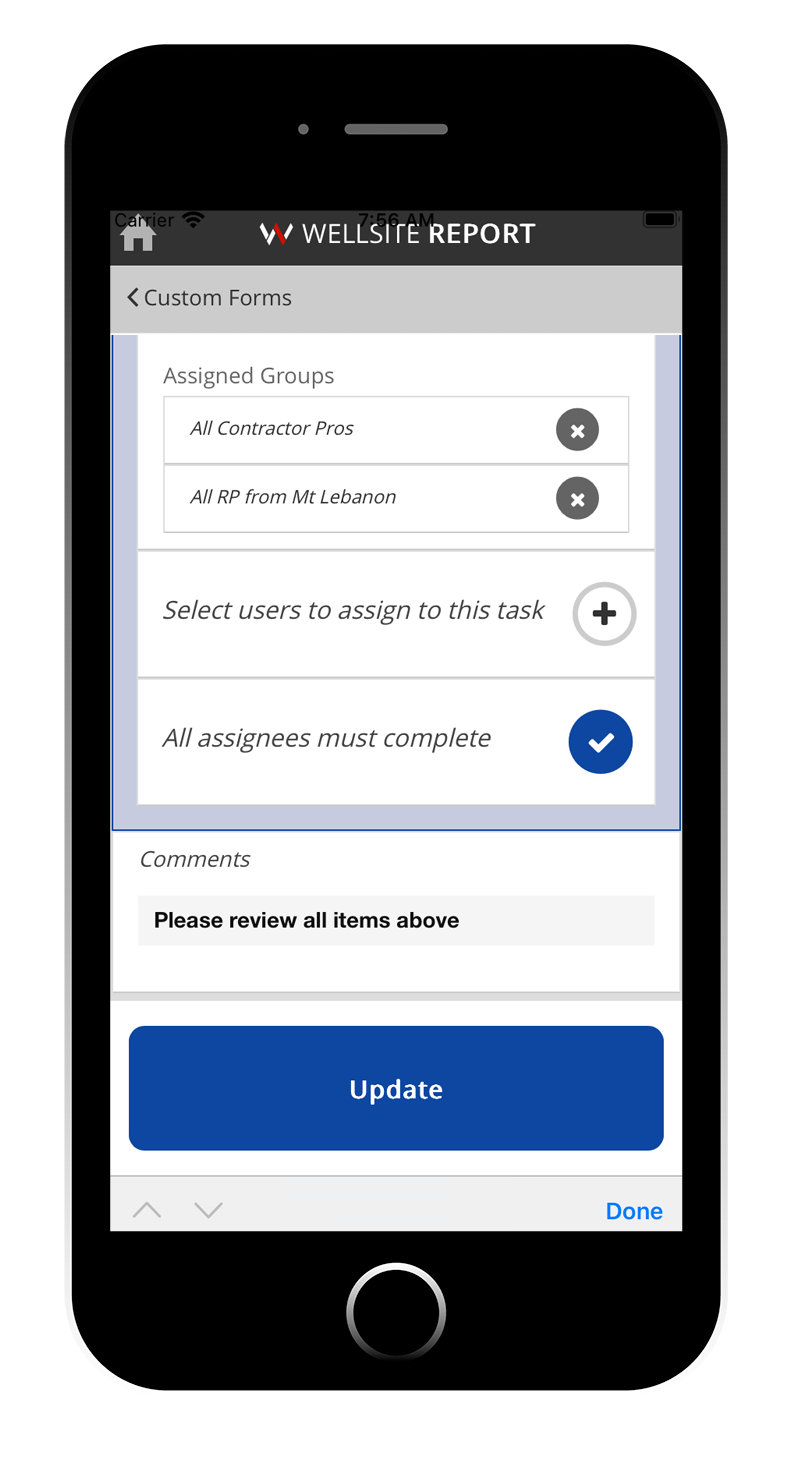

Our custom form builder service works seamlessly in tandem with our equipment module. We can re-create your existing paper or digital forms that can be completed and submitted on mobile or desktop devices. This makes form completion quick and convenient and eliminates the need for paper at the job site. Custom forms are great for inspections and making checklists to maintain equipment, facilitating a tighter rein on expenses.

Find out more about how Wellsite Report can help your company stay within budget and mitigate higher interest rates tied to capital expenditures.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Although oil and gas producers are trying to get more out of existing wells than from drilling new ones, 2023 is on pace to be a record year for domestic oil and gas production. In this period of reduced exploration but peak output, wireline service companies and fracking service companies could greatly benefit from using Wellsite Report software.

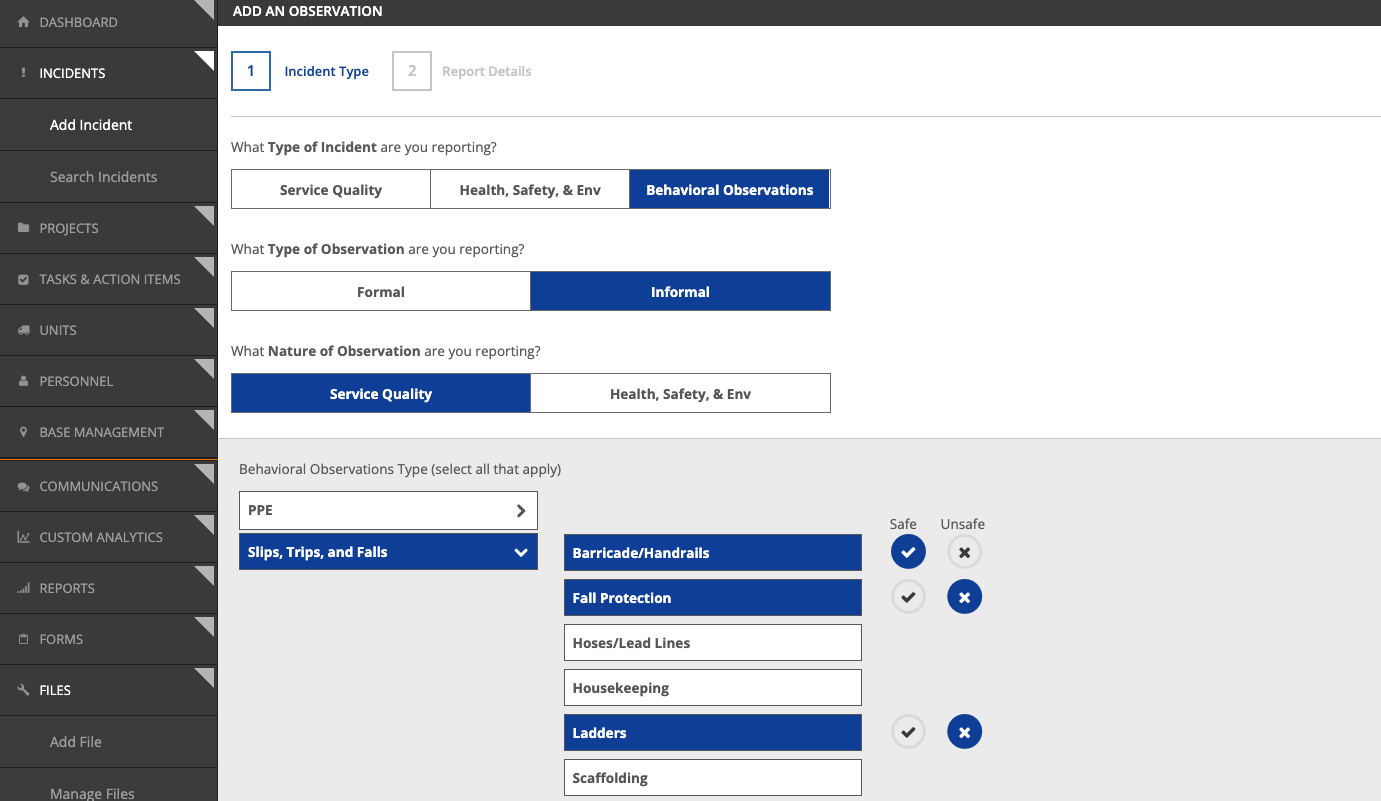

Wireline and fracking service companies are looking for a better way to do reporting, especially with regard to observing service failures and tracking safety incidents. Until recently, most companies filed reports using a printed form or a digital form designed with word-processing or spreadsheet software. These printed and digital forms, however, require more work to log and suffer from a lack of intuitive workflows.

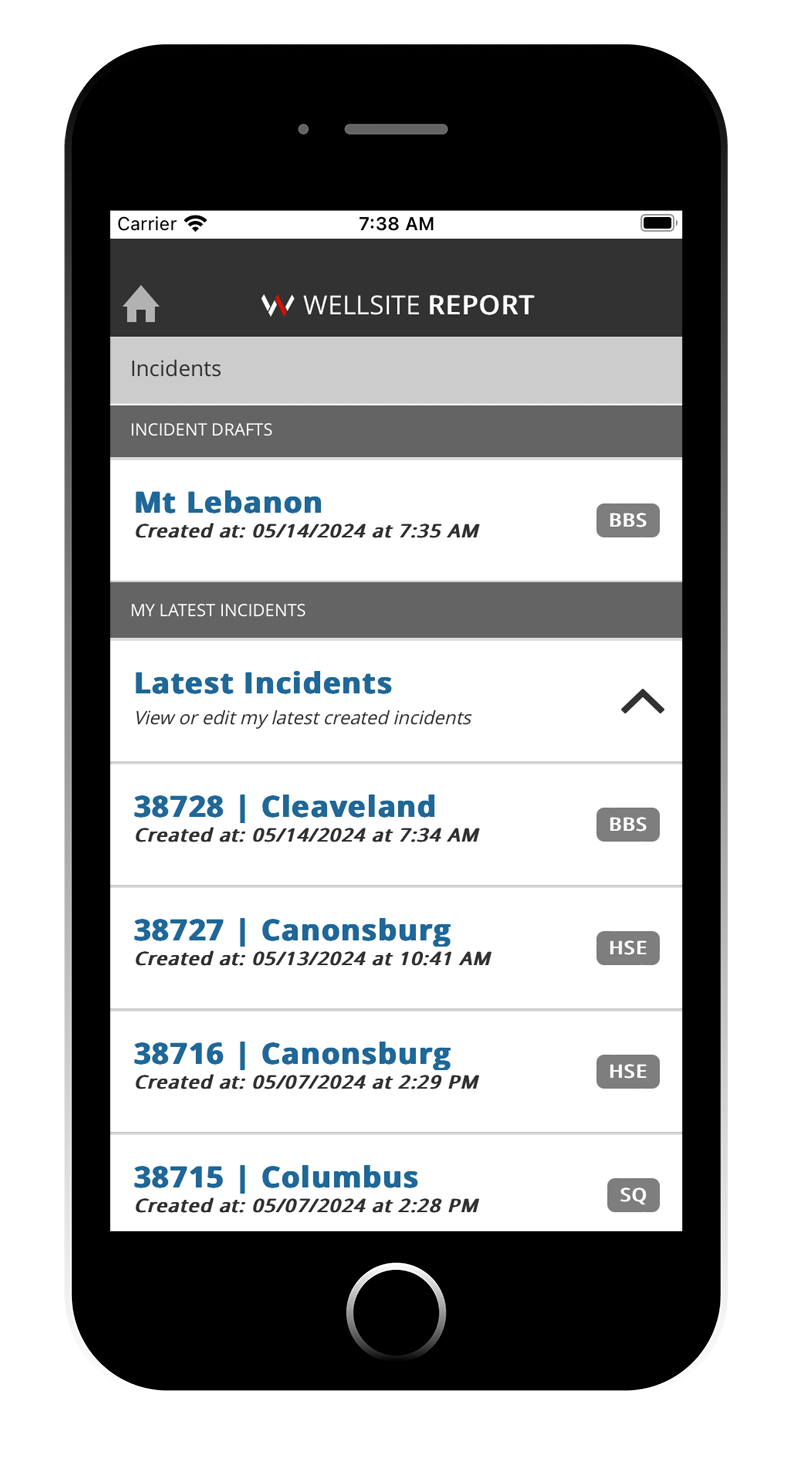

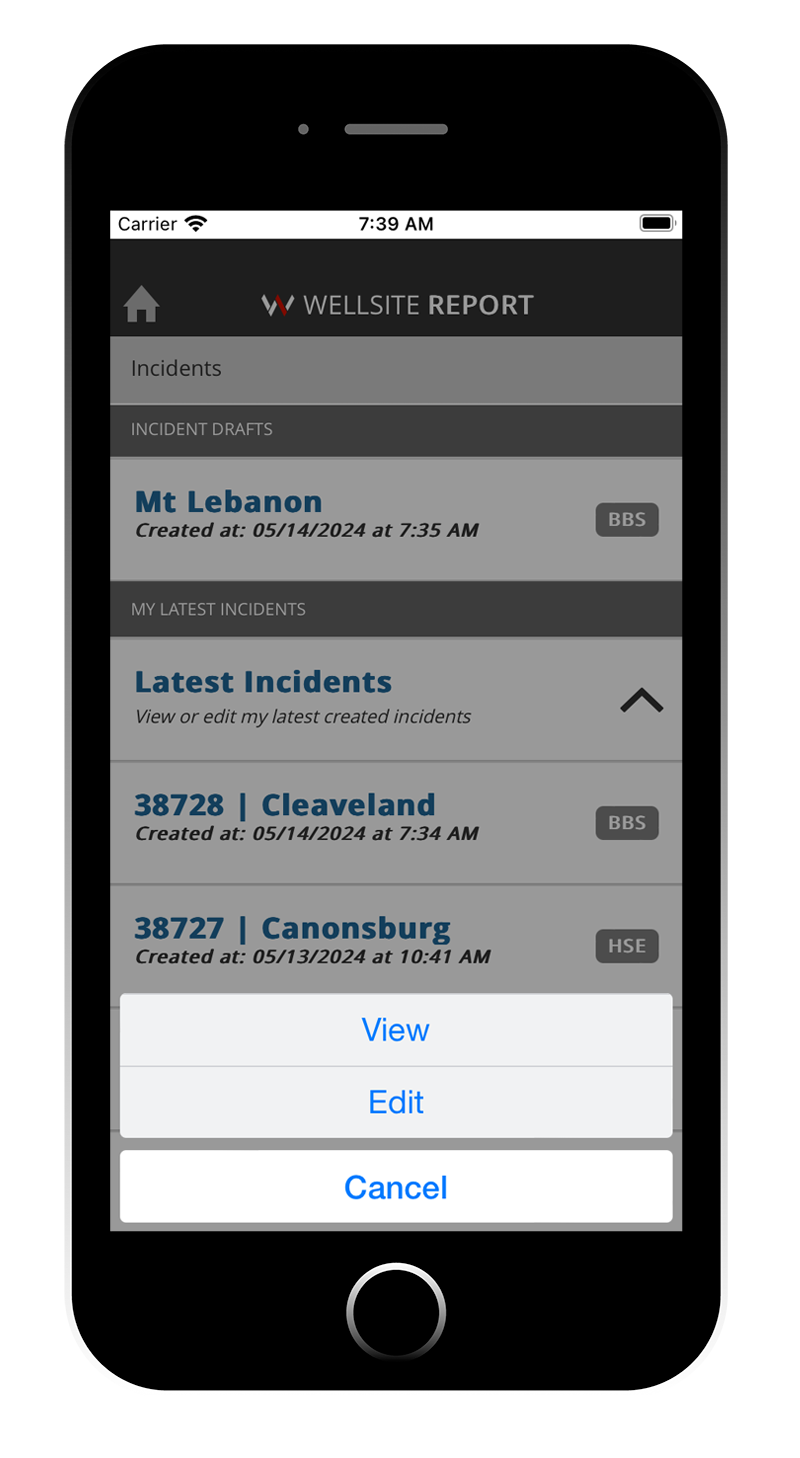

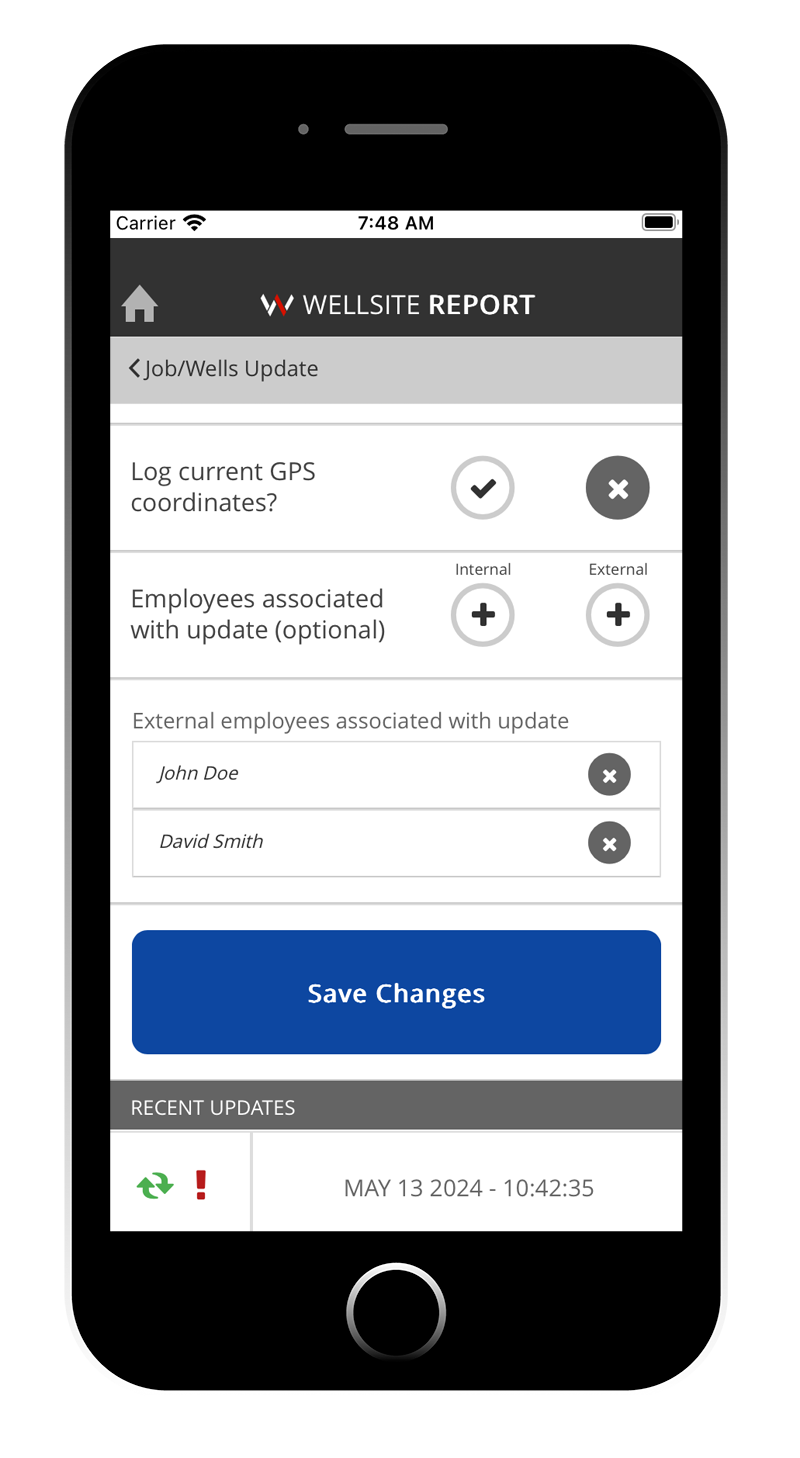

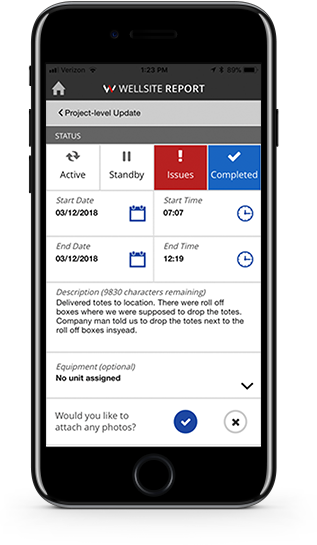

Fortunately, Wellsite Report’s cloud-based software for mobile devices features a built-in reporting system.

Our innovative software makes it easy for field workers to capture and report incident data pertaining to:

Good reporting of SQ failures can lead to better performance of crews at the wellsite. Our software can be customized to include specific failures, but most wireline and fracking failure categories are already included in its standard version. In addition, our solution facilitates easy reporting of BBS observations and near-miss incidents to help reduce worker risk.

With field workers using Wellsite Report, wireline and fracking service companies can demonstrate their solid system of reporting to clients and potential clients. Failures and safety issues are always discussed at quarterly meetings between service companies and client management teams, and it’s imperative that contractors provide them with consistent incident reporting and proof of corrective actions taken.

Wellsite Report makes it all happen. We help keep wireline and fracking service companies on the job.

Wellsite Report’s stage-based updates can also be leveraged for process-intensive work. For example, our software’s stage-based updating tracks when a wireline is used to:

Next, our software can track when a fracking service company:

The wellsite’s operator can then consider the combined efforts of both service companies to be a completed stage.

Find out more about how Wellsite Report can improve your incident reporting, corrective action response, and updates when work is stage-driven.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Oil exploration is expensive, and not without its risks, but it can be quite lucrative for a production company when a substantial reserve is identified. However, many oil fields are in remote, hard-to-reach locations. Before upstream activities like drilling and extraction can take place, a service company is contracted to construct one or more roads that enable heavy rig equipment to be delivered to the remote site.

Building an access road can be a challenge, especially since few things about site preparation are ever routine, but Wellsite Report makes the task easier for service companies.

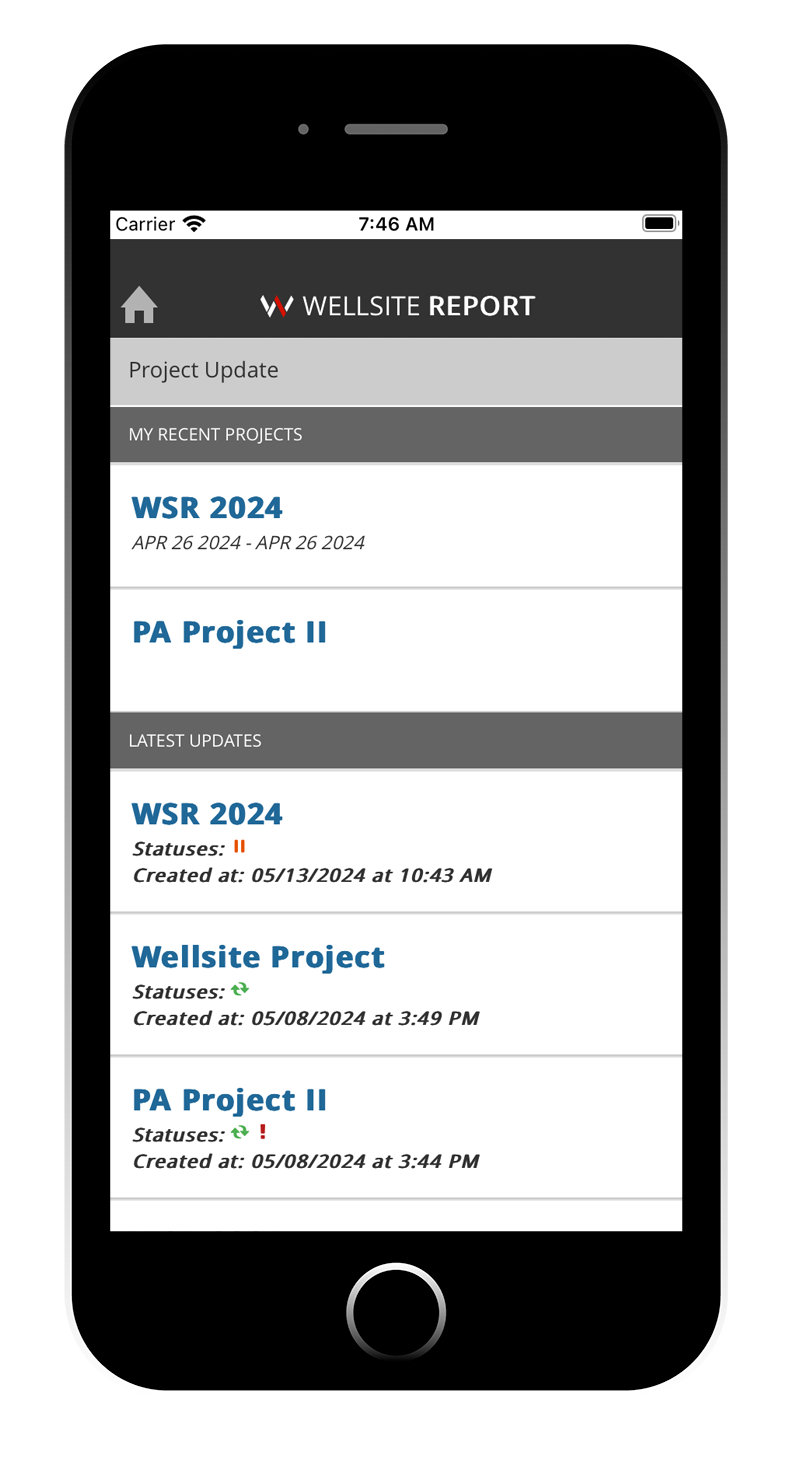

Wellsite Report enables site prep PMs to manage their jobs more effectively. It not only provides real-time updates of work completed, but also enables PMs to address unforeseeable issues and better handle unanticipated delays. With Wellsite Report software, PMs can:

Additionally, Wellsite Report’s cloud software enables PMs to access a full electronic archive of all project updates.

A service company that finds a better way to manage site prep for a production company is likelier to be awarded future maintenance contracts for road and midstream pipeline maintenance. Projects could include mowing, trimming, and side cutting, as well as fencing, planting, and weed control.

A wide variety of service companies that specialize in oil field operations can use Wellsite Report to improve their job management.

After creating a project, jobs or wells can be added. These can be used to show work done to a specific well or used to segregate the updates, incidents and form data of the different jobs performed on site. Example jobs include, but are not limited to the following:

With Wellsite Report’s Project View feature, PMs can quickly check out data pertinent to a particular project or jobs associated within projects with graphs that track status updates and incidents. For custom visualizations, ask about our custom analytics module.

Find out more about what Wellsite Report can do for you — and how much better project management can be going forward.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Natural disasters such as floods, fires, tornadoes, and major storms can occur most anywhere and wreak havoc upon your company’s infrastructure and assets. That’s why you need to execute an effective rapid response that ensures continuity of operations and mitigates harm to people and property in surrounding areas. Wellsite Report helps make it happen.

When disaster strikes, Wellsite Report enables workers on scene to assess the situation and fill out a custom emergency response form. This can help your management team confirm your field employees are correctly following associated procedures, helping to protect personnel and equipment.

In addition, Wellsite Report’s health and safety (HSE) incident reporting logs injuries and damage to equipment and the environment. This report’s data fields enable workers to capture a wide variety of data, from location of any bodily injuries and their severity to the volume of oil, gas, or other liquid lost in a possible spill or uncontrolled release.

Wellsite Report’s real-time incident reporting and incident management workflow enable workers to respond quickly and more effectively to a bad situation, plus they complement your company’s behavior-based safety (BBS) program. Historic and trending BBS data can be used to identify areas where potentially hazardous situations could occur, either before, during, or in the wake of a natural disaster.

Wellsite Report’s real-time notification system immediately alerts all pertinent employees via email when an incident happens during a natural disaster. These real-time alerts provide a summary of the event type, including its location. The field employee submitting the alert can also attach photos to the summary to emphasize a greater need to address the situation. Email alerts can also be filtered by incident type and severity, facilitating a rapid response to a single location or multiple areas hit by an earthquake, flood, fire, tornado, or major storm.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Other companies tout how easy it is to use their field reporting software. But no competing product is simpler to learn — or easier to use — than Wellsite Report, which enables you to optimize your oil and gas operation. Here are four good reasons why you should make it an essential part of your business.

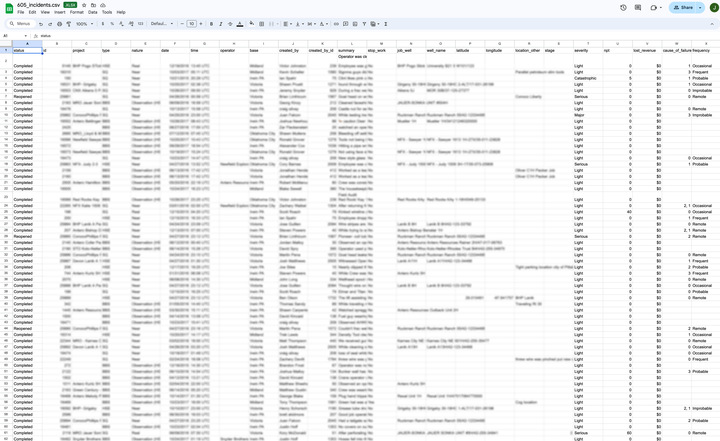

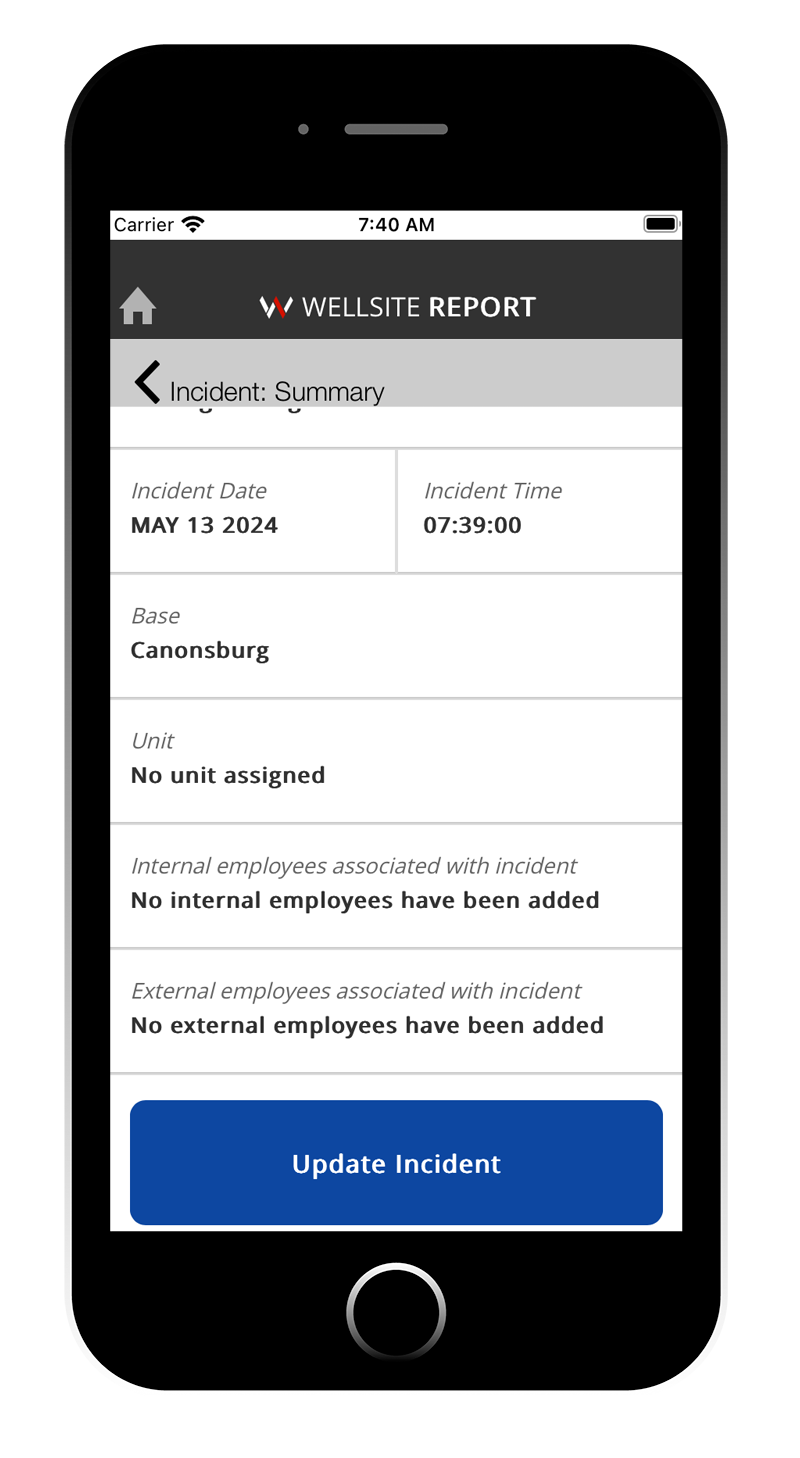

The ability to capture and report incident data to the management team is critical. Wellsite Report makes incident reporting a breeze. Its intuitive workflow facilitates the capture of information on site, and field workers can easily create a report to send to the management team. Management can also export multiple field reports and analyze them for particular data trends.

When it comes time to create a final, professional-looking report, Wellsite Report has a standard reporting format that takes the guesswork out of its structure. You can even import reports created in a third-party word processor program and save them in Wellsite Report’s incident management workflow.

Our cloud-based software enables companies to have a full electronic archive of all reports, and these documents can easily be shared with relevant internal and external parties.

Supervisors can use Wellsite Report’s incident management workflow to quickly assess the impact of events, communicate information to relevant parties, and take swift, corrective actions. You can also assign tasks with due dates to verify measures are completed, easily view all action items in progress, and receive overdue notifications when employees fall short of assigned responsibilities.

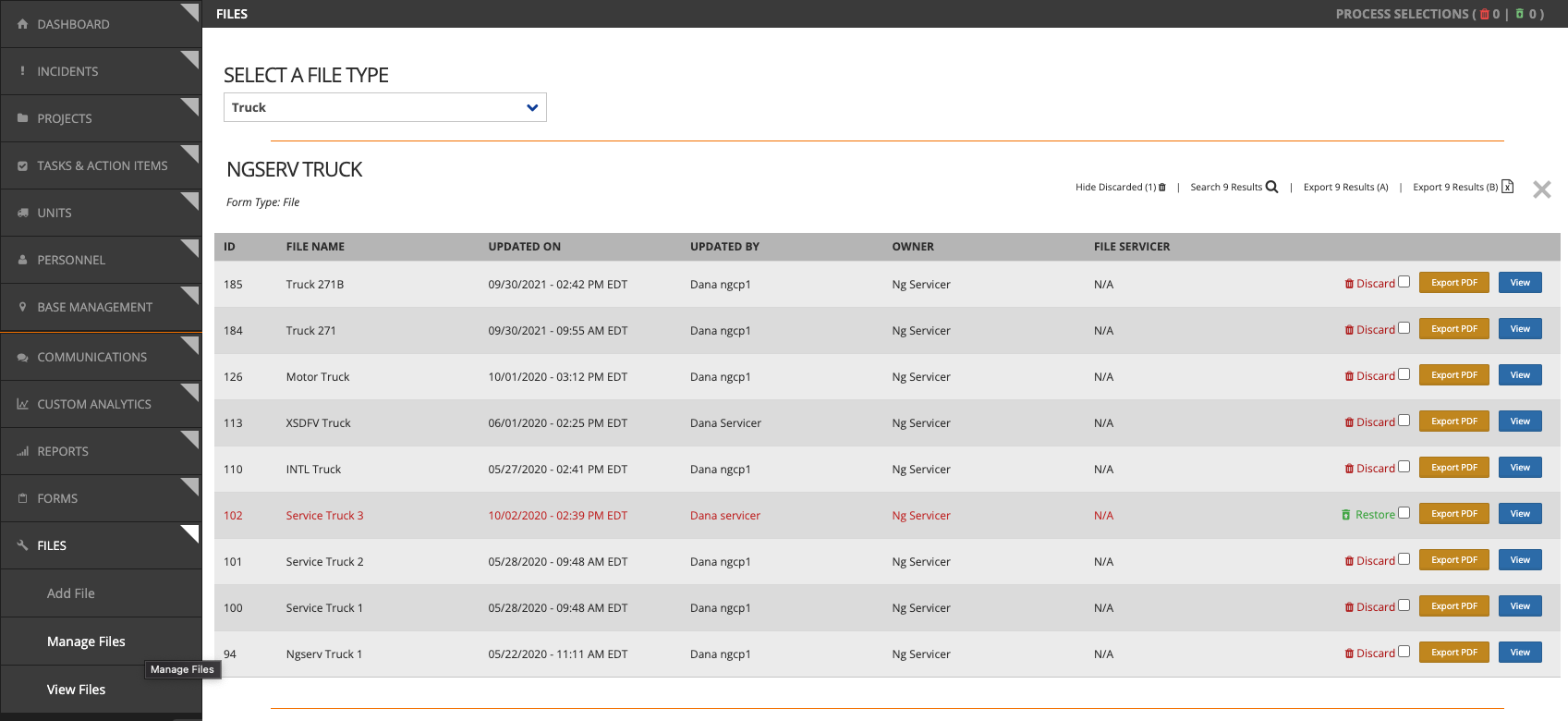

Got equipment? Of course, you do — which means maintenance needs to be performed on the regular.

Wellsite Report’s form building service can create custom digital forms so you

can manage unique equipment types — and make preventive maintenance easy. And if you rent equipment to another

company, custom email notifications can be sent to renters about equipment maintenance.

Wellsite Report can digitally recreate your company’s paper forms, making paper a thing of the past at the job site.

Custom forms can include fields for GPS location, signature, file uploads, and more. Our form building service can add or change fields on any digital form in a snap, and all users will have the latest version the next time they use it. Create a PDF of any completed form and export it on demand for editing, archiving, or analyzing.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

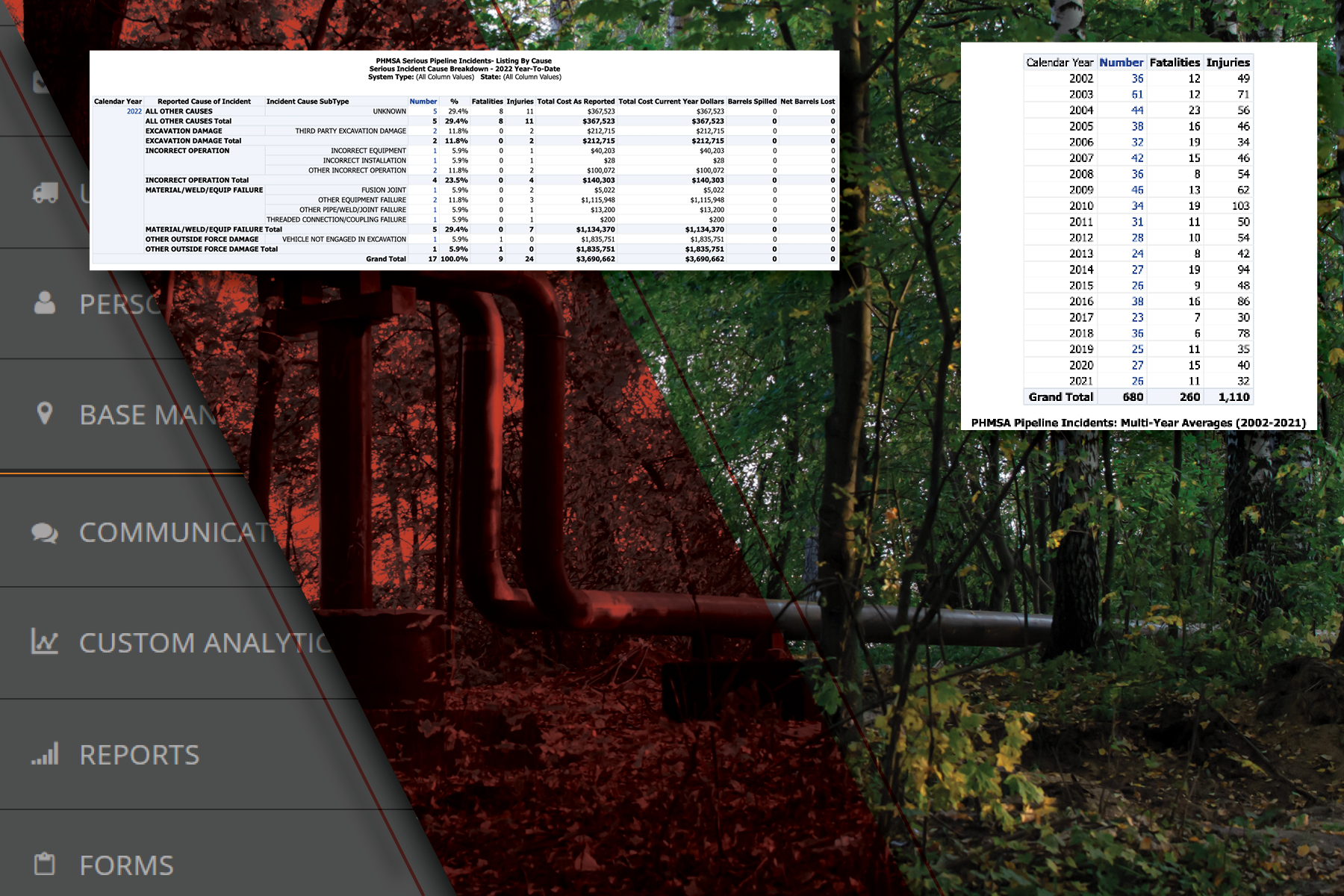

Despite the greater emphasis placed on safety and mitigation procedures, serious incidents continue to plague the oil and gas industry. While major international players can absorb financial losses resulting from multiple breakdowns, structural and environmental damage, and litigation, just one incident of incorrect operation or equipment failure can put an enterprising small oil or gas company at tremendous risk.

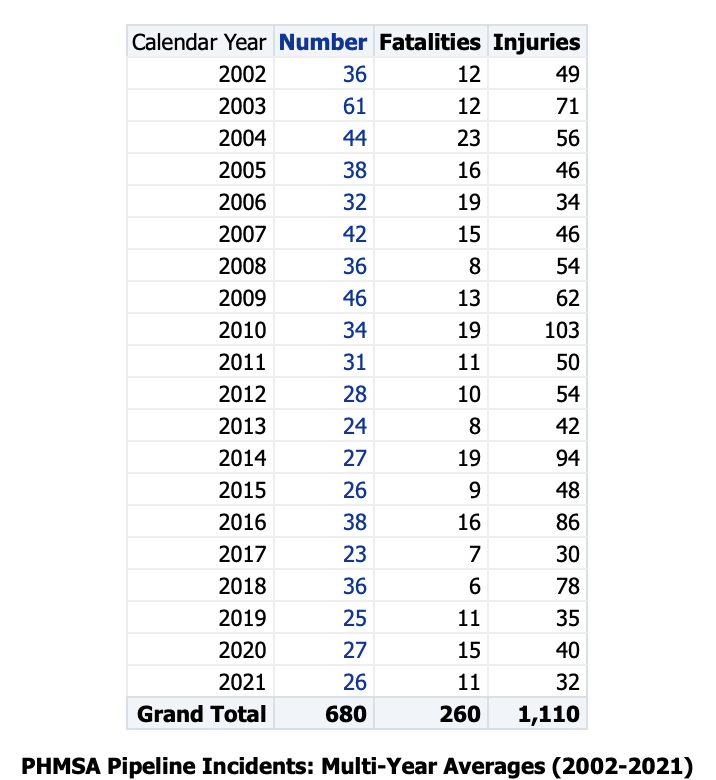

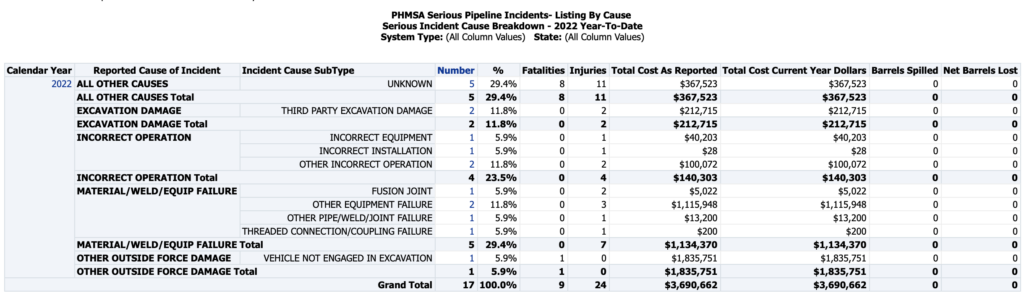

Between 2002–2021, there was an average of 34 serious pipeline incidents per year, with an average of 13 fatalities and 56 injuries annually. Through November 2022, there were 17 incidents, 9 fatalities, and 24 injuries.

Source: US Department of Transportation Pipeline and Hazardous Safety Administration

Source: US Department of Transportation Pipeline and Hazardous Safety Administration

Although these pipeline statistics are below their 20-year highs, the oil and gas industry experiences adverse incidents across all lines of operation. Three leading causes of incidents pertain to training, turnover, and technology.

Easy to implement and even easier to work with, the versatile Wellsite Report app stands apart from other oil and gas reporting software for incident reporting and data capture. It enables field workers to quickly create detailed reports on safety incidents and service quality failures, alert relevant parties in real time that an incident has happened, and use an incident management workflow to assess incidents and take corrective actions. Plus, you can digitize your company’s existing forms for mobile and desktop use to eliminate paper at the job site.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Jodi Rell, who served as the 87th governor of Connecticut, said, “At the end of the day, the goals are simple: safety and security.” How very true. Yet while the goals may be simple, the means to achieve them can be complex and costly.

The oil and gas industries require multiple insurances: general liability, environmental liability, property insurance, healthcare insurance, and disability insurance. You can insure anything. Commercial property insurance will help you mitigate the costs of repair or replacement of structures, equipment, and physical property from theft, vandalism, and fire. It can be costly, but it’s not optional.

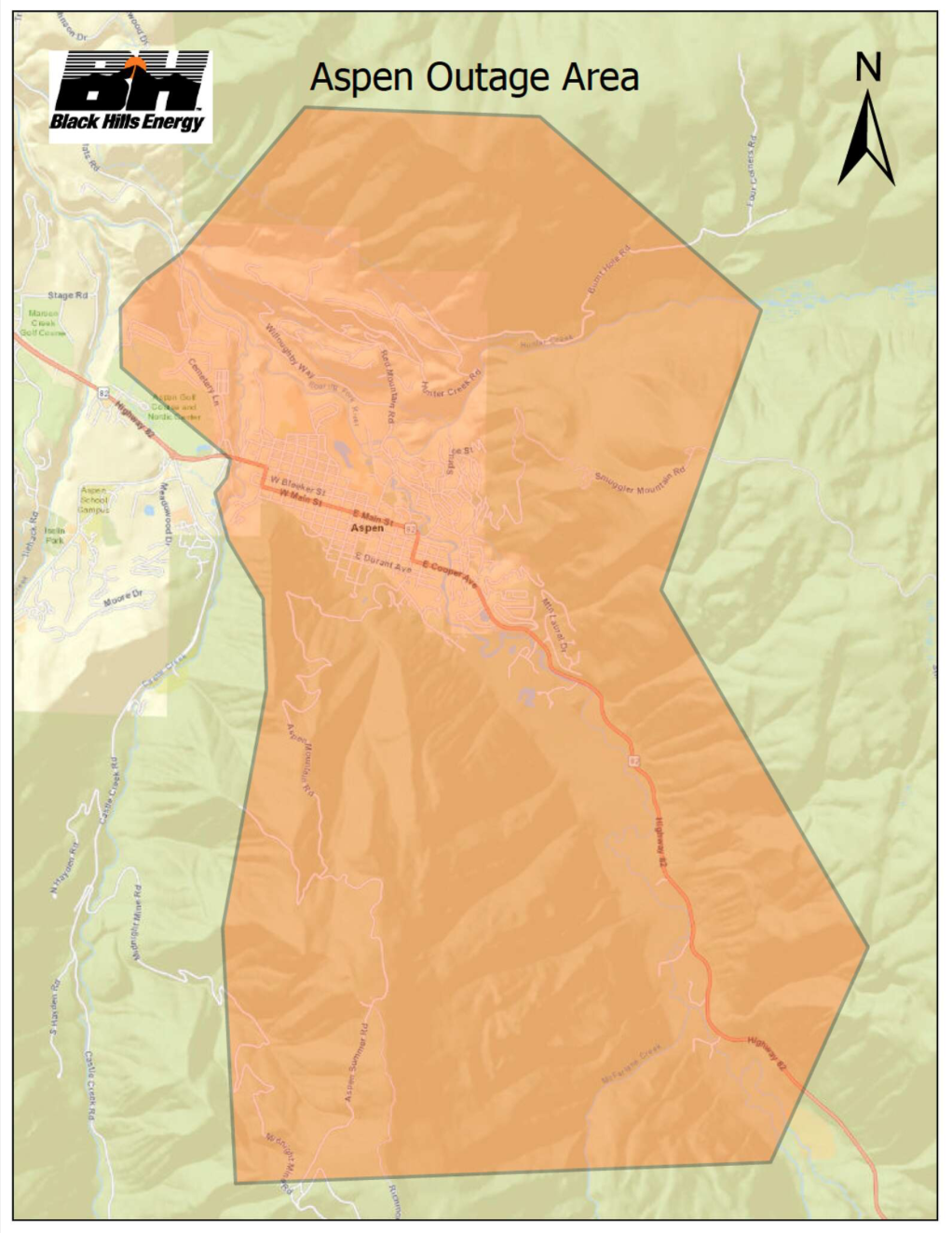

Take the sabotage case of Aspen’s Black Hills Energy. On December 26, 2020. Despite chains and locks, valves in three separate sites were turned to depressurize the gas flow, leaving many residences without heat or hot water.

The solution? Technicians from Black Hills and at least four other energy companies had to drive, in the Aspen snow, to manually turn off roughly 3,500 residential gas meters to secure and test the system. Later, they had to return to all those homes to relight pilot lights. Approximately 40 to 60% of the residences had someone at home during the technicians’ first attempt to restore energy. The city of Denver provided 4,000 space heaters for distribution, which required pre-emptive measures to be taken to prepare for the extra draw on the electrical grid that the heaters would create.

While no group has claimed responsibility for the incident, “Earth First!,” the name of a radical environmental organization, was written on one of the pipelines. The total cost to resolve the incident is estimated to be approximately $1.4 million. Fortunately, no one was injured.

Source: Black Hills Energy

Likewise, damage — intentional or otherwise — to offshore production sites, will also have far-reaching effects well beyond the rig site. An incident at an offshore facility could cause extensive environmental damage that has a devastating impact on the economies of coastal areas, as well as tragic ramifications for the environment and its natural inhabitants.

According to the National Petroleum Council (NPC), of a dozen physical infrastructure components of the oil industry, the three with a “High” level of vulnerability to intentional damage or disruption were: refineries, product pipeline interconnects, and product distribution (rail, truck, and barge). The two that were characterized as having a “Low” level of vulnerability were: the strategic petroleum reserve (SPR) and crude oil pipelines. However, the NPC considered the impact on supply, economy, and safety to be “High” for 10 of the 12 components.

As for the gas industry, the only one of nine physical infrastructure components rated to have a “High” level of vulnerability was: city gate (LCD) interconnections. Gas processing plants and gas compressor stations were rated to have “Medium” vulnerability. The NPC also considered the impact on supply, economy, and safety to be “High” for seven of the nine industry components.

In the event of a site incident, SMS text messages can be sent directly from the Wellsite Report website to the mobile devices of any number of personnel — at any time, 24/7. Whether it’s a quick update, an alert, a report, or other information — even an image or PDF attachment, your message can be sent immediately from the field.

From a proactive standpoint, project/site managers can use Wellsite software to manage the installation and maintenance of barriers that protect compressor stations, main load valves, right-of-way easements, meter and regulation stations, substations, water impoundments, and well pads. The software can also be used to schedule and track the delivery, storage, and deployment of chain-link, electrified, or non-conductive vinyl temporary or security fencing.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

In a previous blog, we discussed pipeline safety and the main causes of pipeline leaks. While it did cite some statistics about spill incidents affecting U.S. waterways, the article focused more on leaks occurring at overland pipelines.

Today’s focus is on offshore spills, specifically along the southern California coastline.

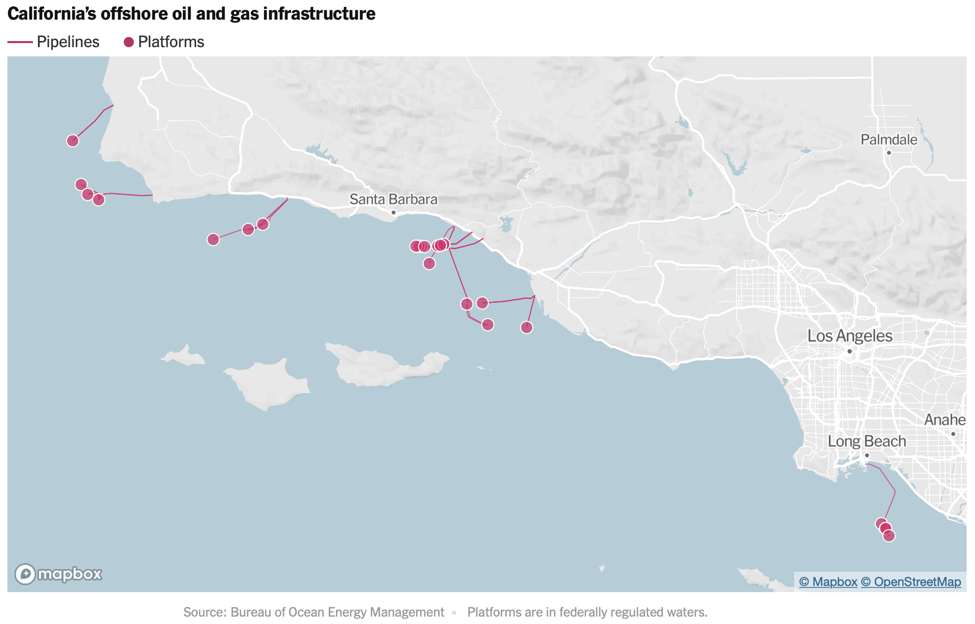

As of the posting of this article, an estimated 144,000 gallons of oil have spilled into southern California waters as a result of an underwater pipeline rupture. The platforms and pipelines in the area of the leak were installed 4.5 miles off the California coast in the early 1980s by a consortium led by Royal Dutch Shell.

After four decades of operation, one would expect a wear-and-tear issue to be the cause of the spill. But the pipeline in question, now operated by Houston-based Amplify Energy, which also operates the former Shell platforms, appears to have been damaged by something beyond Amplify’s control.

In shipping terms, a port arrival does not necessarily mean a ship is in dock. It simply means a vessel has reached its destination even if it is still offshore awaiting port entry.

According to MarineTraffic, a navigation service that tracks data from ship transponders, it appears, however, that the Rotterdam Express didn’t stay put at SF-3. After initially dropping anchor 2000 feet from the Amplify pipeline, the ship moved thousands of feet to the south about 5 p.m., on a track that took it directly over the pipeline lying 100 feet below on the sea floor. The ship then returned to SF-3 10 minutes later.

Hours later, around midnight, the Rotterdam Express moved yet again but soon returned to its assigned anchorage. At 8 a.m. the morning of September 23, the shipping vessel moved one more time before returning to SF-3. On Sunday October 3, the Rotterdam Express moved to the docks at Long Beach to unload.

Preliminary reports from Coast Guard divers suggest that an anchor hooked on to a bend in the pipeline and dragged it 105 feet from where it was. Speaking before reporters, Amplify Energy CEO Martyn Willsher said, “The pipeline has essentially been pulled like a bowstring.”

Hapag-Lloyd, the shipping company that operates the Rotterdam Express, denies any role in the spill. And the company may be correct in its assessment. At an October 8 press conference, the Coast Guard said that the underwater pipeline was likely initially damaged by a ship’s anchor several months to a year ago. In addition, the spill could be the result of multiple anchor strikes to the pipeline after the initial strike.

Controversy has also ensued over as to when Amplify knew there was damage to its operations and why the company didn’t alert federal agencies about the oil spill until six hours after initial low-pressure alarms sounded.

The global supply chain has been disrupted, and it all ties back to the pandemic.

In brief, China will shut down its ports for two weeks even if literally only one dockworker tests positive for COVID. Most recently, it happened in Ningbo, the world’s third-busiest container port.

Shipping costs have also skyrocketed as there is a shortage of cargo containers, and Asian exporters are in bidding wars to secure space on ships. In addition, cargo vessels are leaving Asian ports much later than normal and losing docking slots at their Pacific coast destinations.

According to data from the Marine Exchange of Southern California, there were 90 container ship port arrivals in Los Angeles on Tuesday October 5. Sixty-three of those ships were waiting offshore, with some anchored as far as 20 miles from the coast.

Ships at port can now wait in their anchorage spots for up to a month. Currently, half a million cargo containers are stuck off the coast of southern California waiting to be unloaded. That’s because the coronavirus has reduced the longshoremen workforce, causing all of our west coast ports to operate well below their capacity.

California is the nation’s third-largest oil-producing state, having more than 200 miles of sea floor pipelines that serve 23 offshore platforms off the coasts of Santa Barbara, Ventura, Los Angeles, and Orange counties.

Wellsite Report enables platform operators to better manage their midstream transportation and address pipeline leaks. Our real-time incident reporting includes a summary, location, and incident type. Photos can also be attached to provide more details.

But we’re more than just reporting software. Use Wellsite to assign corrective actions and ensure incident resolution workflow and follow-up. As tasks are done, they can be marked “complete” in the app, so there’s never any question about the status of work.

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Remember our last release – subcategory addition for observation incidents?

Now we have an even better way to report them

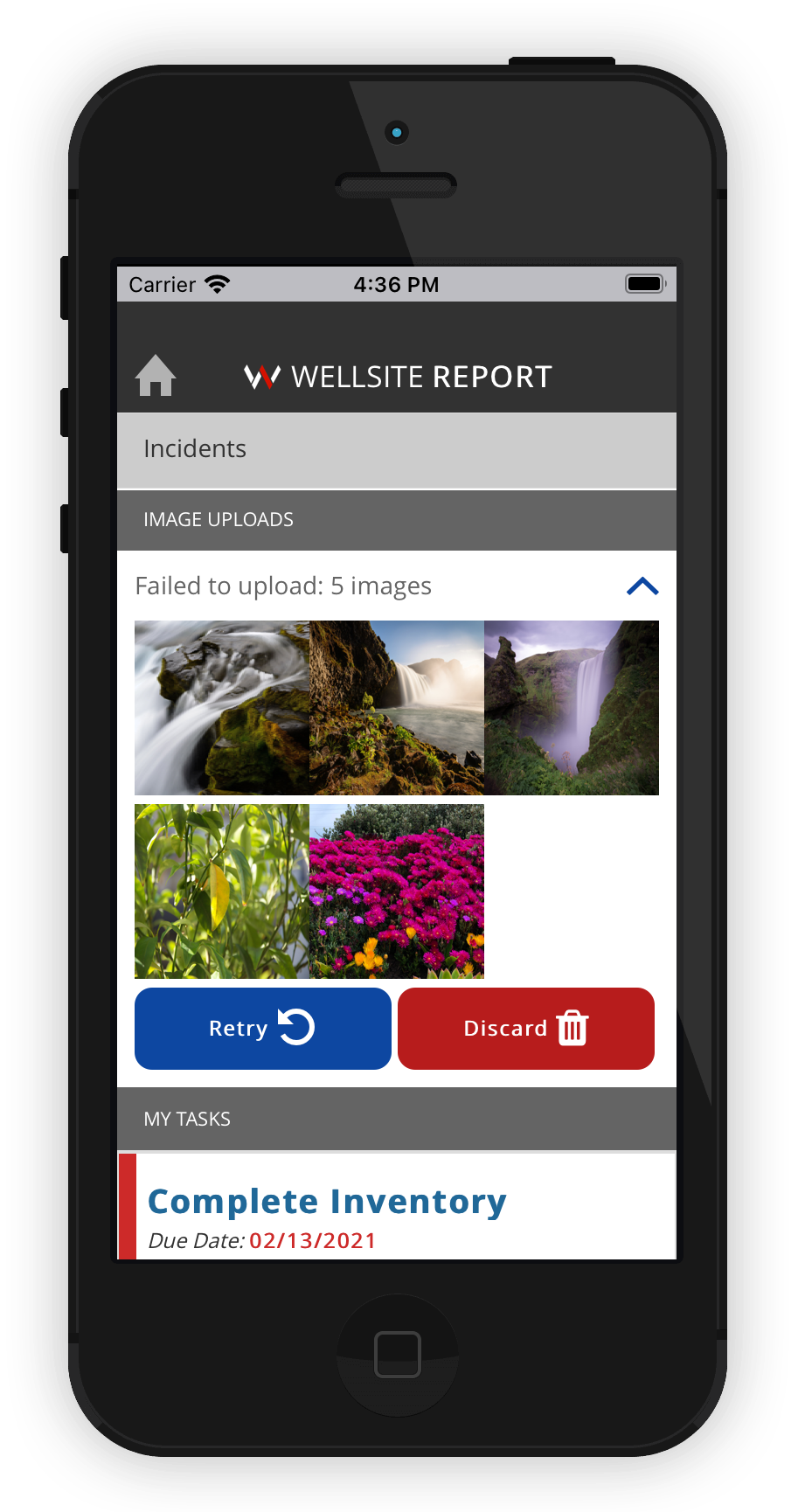

Ever lose connection on your phone when out on the road? Or get frustrated with low speed wi-fi when trying to work? Or maybe you’re just in a no-signal area

Try clearing your browser’s cache. If you still don’t see all our awesome updates, contact us.

Questions? Contact Us at

INFORMATION@DIGITOIL.COM

Sales/Billing: 1-877-626-7552 EXT 0

for Sales, 1 for Billing

Tech Support: 1-877-208-6153